Satisfied with our top-end drawn over mandrel, duplex stainless steel pipes, duplex pipe and warm after-sale service, our customers spoke highly of our technical personnel in terms of technical assistance and support. Our company keeps accelerating the pace of business innovation, and our processes can adapt to business needs on demand. We will adhere to the requirement of being stronger and better, and essentially promote the sustainable development of our company. We have strict requirements on product quality, providing customers with high-quality products and services is our tenet. We strive for excellence in brand value, technology research and development, product quality, cost control, energy saving and emission reduction.

GB/T3094 OMEGA Shaped Steel Tube and Pipe

Material, Specification, Key Features (Detailed Introduction)

The GB/T3094 standard specifies the requirements for omega-shaped steel tubes and pipes, which are widely used in various structural applications. These tubes are characterized by their unique omega shape, providing enhanced strength and stability compared to traditional round or square tubes. The standard outlines the material specifications, dimensions, and mechanical properties required for these products.

Key Features:

Shape: Omega-shaped design for improved structural integrity.

Versatility: Suitable for various applications, including construction and manufacturing.

Strength: Enhanced load-bearing capacity due to the cross-sectional shape.

Corrosion Resistance: Often treated or coated to improve durability.

Chemical Composition

The chemical composition of omega-shaped steel tubes is critical for ensuring their performance and durability. Below is a table presenting the typical chemical composition for the steel grades used in GB/T3094.

| Element | Composition (%) |

| Carbon (C) | 0.12 - 0.20 |

| Manganese (Mn) | 0.30 - 0.60 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.025 |

| Silicon (Si) | 0.15 - 0.40 |

| Chromium (Cr) | ≤ 0.25 |

| Nickel (Ni) | ≤ 0.25 |

Mechanical Properties

The mechanical properties of omega-shaped steel tubes are essential for their application in structural engineering. The following table summarizes the key mechanical properties:

| Property | Value |

| Yield Strength (MPa) | ≥ 235 |

| Tensile Strength (MPa) | ≥ 400 |

| Elongation (%) | ≥ 20 |

| Hardness (HB) | ≤ 180 |

Physical Properties

Understanding the physical properties of omega-shaped steel tubes is crucial for their application in various environments. The following table presents these properties:

| Property | Value |

| Density (g/cm³) | 7.85 |

| Melting Point (°C) | 1425 - 1540 |

| Thermal Conductivity (W/m·K) | 50.2 |

| Electrical Resistivity (μΩ·m) | 0.00001724 |

Process Performance

The process performance of omega-shaped steel tubes is vital for their manufacturability and usability. Below is a table summarizing the process performance characteristics:

| Property | Value |

| Weldability | Good |

| Formability | Excellent |

| Machinability | Moderate |

| Surface Finish | Smooth |

Steel Grade (Detailed Introduction)

The GB/T3094 standard includes several steel grades, each tailored for specific applications and performance requirements. Common grades include:

Q235: A general-purpose structural steel with good weldability and moderate strength.

Q345: A high-strength low-alloy steel, suitable for heavy-duty applications.

S235: A European standard equivalent, known for its good mechanical properties.

These grades are selected based on the specific requirements of the application, including load-bearing capacity, environmental conditions, and fabrication processes.

Application

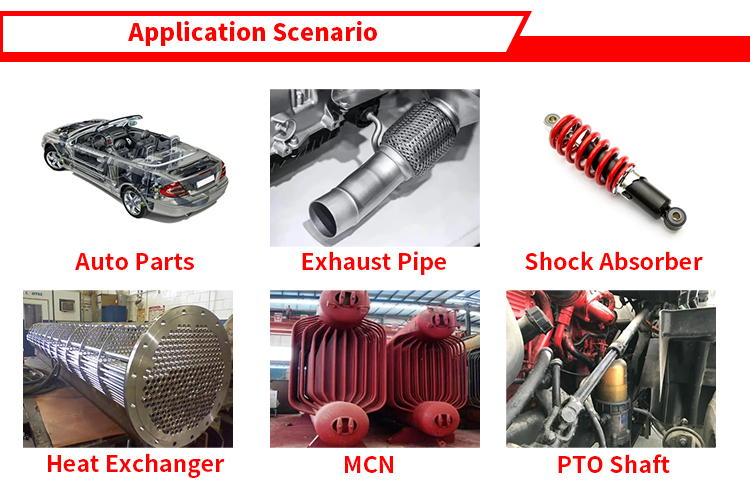

Omega-shaped steel tubes are utilized in various applications, including:

Construction: Used in building frames, bridges, and other structural components.

Manufacturing: Employed in the production of machinery and equipment.

Automotive: Used in vehicle frames and components for enhanced strength and weight reduction.

Furniture: Applied in the design of modern furniture due to their aesthetic appeal and strength.

Possible Alternative Grades

In addition to the standard grades specified in GB/T3094, several alternative grades may be considered based on specific requirements:

ASTM A500: A standard specification for cold-formed welded and seamless carbon steel structural tubing.

EN 10219: A European standard for cold-formed welded and seamless structural hollow sections of non-alloy and fine-grain steels.

JIS G3466: A Japanese standard for structural steel tubes.

These alternative grades may offer similar mechanical properties and applications, providing flexibility in material selection based on availability and cost.

We promise to exchange our best quality 301 316 317 420 Shaped Tube Square Section Shape Stainless Steel Hollow Tube and considerate service for the success of our cooperation with all customers! We have formed a strong market appeal by improving the market value of our brand. We always adhere to the international boutique product quality and the service concept of love, sparing no effort to contribute our own strength to social harmony.

Hot Tags: omega shaped steel tube and pipe, China, suppliers, manufacturers, factory, customized, wholesale, price, OEM, mill, producer, for sale, precision stainless steel tube, astm a312 304, EN 10305-1 Seamless Precision Steel Tubes, EN10305-1 E235 Seamless Steel Tube, carbon steel erw pipe, stainless steel u tube