We have been committed to the production and supply of high-quality sa335 p22, carbon hexagonal steel tube, sa312 tp321, continue to improve the product series, and assist customers in the design, development, and production of customized products for different applications. Intellectual property makes our technical advantage, knowledge advantage and brand advantage transform into market competitive advantage. Our company has established a complete quality assurance system and complete experimental equipment to monitor the entire production process to ensure the stability of product quality. Our high-quality service system and good reputation have been unanimously recognized by customers.

Inconel Alloy 625 Tubing

Overview

Inconel Alloy 625 is a nickel-based superalloy known for its high strength, corrosion resistance, and toughness in extreme environments. Tubing made from this alloy is widely used in applications that demand durability and resistance to oxidation and corrosion at elevated temperatures. Let's dive into the specifics of Inconel Alloy 625 tubing, including its material composition, key features, and various applications.

Material Specification

Material: Nickel-Chromium-Molybdenum Alloy

UNS Number: N06625

Form: Tubing, pipes, sheets, bars, forgings, and fittings

Density: 8.44 g/cm³

Melting Point: 1290–1350°C (2354–2462°F)

Key Features

High Temperature Resistance: Inconel Alloy 625 exhibits excellent performance in high-temperature environments.

Corrosion Resistance: Offers superior resistance to a wide range of corrosive media, including oxidizing and reducing acids.

Strength and Toughness: Maintains strength and flexibility even at cryogenic temperatures.

Weldability: Can be welded without cracking and requires no post-weld heat treatment.

Fatigue Resistance: Shows good resistance to thermal fatigue and cyclic loading.

Chemical Composition

| Element | Percentage |

| Nickel (Ni) | 58.0 min |

| Chromium (Cr) | 20.0–23.0 |

| Molybdenum (Mo) | 8.0–10.0 |

| Iron (Fe) | 5.0 max |

| Niobium (Nb) | 3.15–4.15 |

| Tantalum (Ta) | Included in Nb |

| Manganese (Mn) | 0.50 max |

| Silicon (Si) | 0.50 max |

| Carbon (C) | 0.10 max |

| Phosphorus (P) | 0.015 max |

| Sulfur (S) | 0.015 max |

| Aluminum (Al) | 0.40 max |

| Titanium (Ti) | 0.40 max |

Mechanical Properties

| Property | Value |

| Tensile Strength (MPa) | 930 min |

| Yield Strength (MPa) | 414 min |

| Elongation (%) | 30 min |

| Hardness (Rockwell B) | 88 max |

Physical Properties

| Property | Value |

| Density | 8.44 g/cm³ |

| Melting Point | 1290–1350°C |

| Electrical Resistivity | 1.2 µΩ-m at 20°C |

| Thermal Conductivity | 9.8 W/m·K at 20°C |

| Specific Heat | 0.40 kJ/kg·K at 20°C |

Process Performance

| Process | Description |

| Weldability | Excellent, no pre-heating or post-heating required |

| Formability | Good, can be cold-formed |

| Machinability | Moderate, requires rigid tooling |

| Heat Treatment | Not required for improved properties |

| Annealing | 1010–1065°C, followed by rapid cooling |

Steel Grade

Standard Designation: Inconel Alloy 625

Common Applications: Chemical processing, aerospace, marine engineering, nuclear reactors, oil and gas extraction.

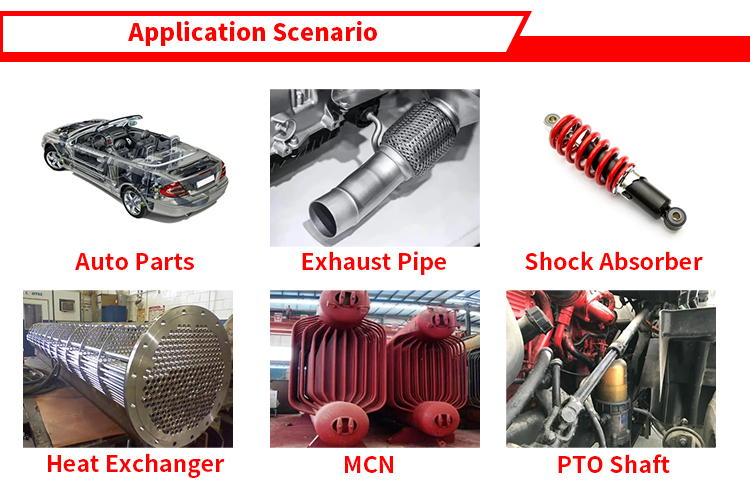

Application

Inconel Alloy 625 tubing is widely used in industries that require resistance to high temperatures and corrosion. Key applications include:

Aerospace: Engine components, exhaust systems, and afterburners.

Marine Engineering: Piping systems, heat exchangers, and fasteners.

Chemical Processing: Acid handling and pressure vessels.

Oil and Gas: Subsea pipelines, risers, and fittings.

Nuclear: Reactor components and control rod drive mechanisms.

Possible Alternative Grades

If Inconel Alloy 625 is unavailable or other properties are required, the following grades can be considered as alternatives:

Inconel 718: Offers similar high-temperature performance with enhanced strength.

Inconel 600: A general-purpose nickel-chromium alloy with good oxidation resistance.

Hastelloy C276: Provides excellent corrosion resistance in a wide range of environments.

Monel 400: Primarily used for its resistance to seawater and steam at high temperatures.

These alternative grades offer varying characteristics depending on the specific requirements of the application.

We always implement the value concept of taking technological innovation as the soul and quality as the guarantee, and strictly abide by the industry standards to manufacture the Best Price N06625/Haynes 625 Stainless Steel Tube/Pipe. A team is defined as a community of employees and management that makes reasonable use of each member's knowledge and skills to work collaboratively to solve problems and achieve common goals. Our company adheres to the enterprise spirit of taking market demand as the guide, constantly researches, develops, and produces new products to meet the needs of our customers.

Hot Tags: inconel alloy 625 tubing, China, suppliers, manufacturers, factory, customized, wholesale, price, OEM, mill, producer, for sale, grade 9 titanium tube, stainless steel pipe 316, p11 pipe, rectangular steel tube, astm a213 t5, a519 1026