We supply you best benefit of money and we're ready to create with each other with seamless rectangular tubing, precision steel tube for pneumatic cylinder, Steel Rod. We take technology as the driving force, customer as the leading, and constantly launch high-tech and good market prospects. Our company constantly innovates technology, develops new products, gradually realizes scientization and standardization, and speeds up the integration with the international market. We promote the company's quality policy to all personnel working for or on behalf of the company, raise quality awareness, and involve all employees in quality improvement. We hope to form a good atmosphere of respect for labor, knowledge, talent and creation, so that dedicated, responsible and responsible employees can share more of the fruits of corporate development.

Rittling Finned Tube Boiler

Introduction

In the world of industrial boilers, the Rittling Finned Tube Boiler stands out as a reliable and efficient choice for various applications. This article will delve into the material, specification, key features, chemical composition, mechanical properties, physical properties, process performance, steel grade, application, and possible alternative grades of the Rittling Finned Tube Boiler.

Material and Specification

The Rittling Finned Tube Boiler is constructed using high-quality materials, ensuring durability and optimal performance. The boiler's key specifications include:

Material: Steel

Tube Type: Finned

Pressure Rating: According to applicable standards

Heat Transfer Area: As per design requirements

Maximum Operating Temperature: Varies based on application

Key Features

The Rittling Finned Tube Boiler offers several notable features contributing to its popularity and effectiveness. These include:

Enhanced Heat Transfer: The finned tube design maximizes the heat transfer area, promoting improved thermal efficiency.

Compact Design: The boiler's compact design allows for easy installation in various spaces.

Versatility: With its ability to operate at varying pressures and temperatures, the Rittling Finned Tube Boiler is adaptable to different applications.

Durable Construction: Built with high-quality steel, the boiler guarantees longevity and resistance to corrosion.

Energy Efficiency: Through its advanced design, the boiler ensures efficient heat transfer, minimizing energy wastage and reducing operational costs.

Chemical Composition

The chemical composition of the Rittling Finned Tube Boiler's steel material is as follows:

| Element | Composition Range (in %) |

| Carbon (C) | 0.15 - 0.25 |

| Manganese (Mn) | 0.60 - 0.90 |

| Phosphorus (P) | Below 0.040 |

| Sulfur (S) | Below 0.040 |

| Silicon (Si) | 0.15 - 0.35 |

| Nickel (Ni) | Below 0.25 |

| Chromium (Cr) | Below 0.20 |

| Copper (Cu) | Below 0.25 |

Mechanical Properties

The mechanical properties of the Rittling Finned Tube Boiler's steel material are as follows:

| Property | Value |

| Tensile Strength | 400 - 550 MPa |

| Yield Strength | 250 MPa (minimum) |

| Elongation | 20% (minimum) |

| Hardness | 170 - 210 HB |

Physical Properties

The physical properties of the Rittling Finned Tube Boiler's steel material are as follows:

| Property | Value |

| Density | 7.85 g/cm³ |

| Thermal Conductivity | 46.6 W/m·K |

| Specific Heat | 490 J/kg·K |

| Melting Point | 1420 - 1460 °C |

| Electrical Conductivity | 1.43 × 10^6 S/m |

Process Performance

The Rittling Finned Tube Boiler is known for its outstanding process performance, as shown in the table below:

| Performance | Value |

| Heat Transfer | Excellent |

| Energy Efficiency | High |

| Pressure Resistance | Reliable |

| Corrosion Resistance | Excellent |

| Service Life | Long |

Steel Grade and Application

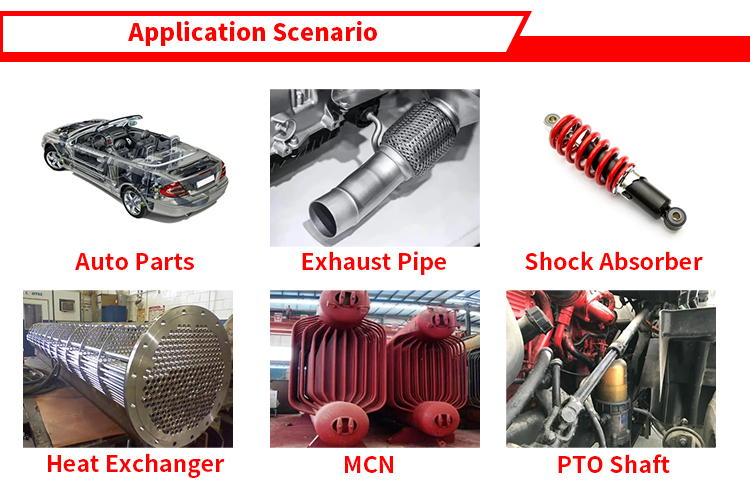

The Rittling Finned Tube Boiler is typically manufactured using carbon steel with a grade of ASTM A192. This grade offers good weldability, high strength, and corrosion resistance, making it suitable for various applications. Some common applications include:

Power plants

Chemical industries

Refineries

Petrochemical plants

Heating systems

Possible Alternative Grades

While the ASTM A192 grade is commonly used, alternative grades that can be considered for the Rittling Finned Tube Boiler include:

ASTM A210

ASTM A192M

ASTM A213

ASTM A179

These alternative grades possess similar properties and provide comparable performance, offering flexibility in project requirements.

Conclusion

The Rittling Finned Tube Boiler showcases its superiority through its material, key features, chemical composition, mechanical and physical properties, process performance, steel grade, application, and possible alternative grades. With its outstanding design, efficiency, and durability, this boiler remains an excellent choice for various industries and applications.

As the market demand for China Manufacturer Factory Waste Heat Recover Boiler Heat Exchanger, P265gh P235gh En10216 Hh Fin Tube Economizer continues to grow, our company continues to develop more valuable products. We focus on the future with a pragmatic and enterprising working attitude and try to satisfy users and achieve a win-win situation with preferential prices and considerate services. The company's quality goal is to pursue excellence, to achieve "zero defects" in products, relying on scientific and technological progress and strict quality management.

Hot Tags: rittling finned tube boiler, China, suppliers, manufacturers, factory, customized, wholesale, price, OEM, mill, producer, for sale, seamless steel tubing, precision seamless steel tube, astm a511, sa213 t5, Sanitary 316L Stainless Steel Tube, b729 uns n08020