The technological content of our astm a335 p9, titanium tube, astm a335 p22 and the level of intelligence continue to improve, and the company's operational quality and quality service capabilities have been significantly enhanced. Our company has a set of "research and development, production, sales, service" high-speed and fast operation system. We always adhere to the tenet of 'focus on quality and sincere service', devote ourselves to the research and development of new technologies in order to offer customers with high-quality services. We have a scientific internal organization and a perfect, efficient and reasonable operation system to make our company more adapt to the needs of market competition.

Welding Titanium Straight Pipe

Titanium straight pipes are critical components in various industries due to their exceptional strength-to-weight ratio, corrosion resistance, and high-temperature performance. Understanding the material properties, chemical composition, and welding processes is crucial for ensuring the integrity and reliability of titanium straight pipes.

Material

Titanium straight pipes are typically manufactured using high-quality titanium alloys such as Grade 2 (Ti-CP) or Grade 5 (Ti-6Al-4V), chosen for their excellent mechanical properties and corrosion resistance.

Specification

Length: Customizable

Diameter: Variable based on application requirements

Wall Thickness: As per industry standards

Key Features

High strength-to-weight ratio

Exceptional corrosion resistance

Excellent high-temperature performance

Low thermal expansion coefficient

Biocompatible

Chemical Composition

| Element | Grade 2 (Ti-CP) | Grade 5 (Ti-6Al-4V) |

| Titanium | 99.2% min | 90.0%-96.0% |

| Aluminum | - | 5.5%-6.75% |

| Vanadium | - | 3.5%-4.5% |

| Iron | 0.30% max | 0.30% max |

| Oxygen | 0.25% max | 0.20% max |

| Carbon | 0.10% max | 0.08% max |

Mechanical Properties

| Property | Grade 2 (Ti-CP) | Grade 5 (Ti-6Al-4V) |

| Tensile Strength | 345 MPa | 895 MPa |

| Yield Strength | 275 MPa | 825 MPa |

| Elongation | 20% min | 10-15% |

| Hardness (HB) | 130 max | 330 max |

Physical Properties

| Property | Grade 2 (Ti-CP) | Grade 5 (Ti-6Al-4V) |

| Density (g/cm³) | 4.51 | 4.43 |

| Melting Point (°C) | 1668 | 1660 |

| Thermal Conductivity | 20.6 W/mK | 6.7 W/mK |

Process Performance

Weldability: Moderate

Machinability: Fair

Corrosion Resistance: Excellent

Steel Grade

Grade 2 (Ti-CP) or Grade 5 (Ti-6Al-4V)

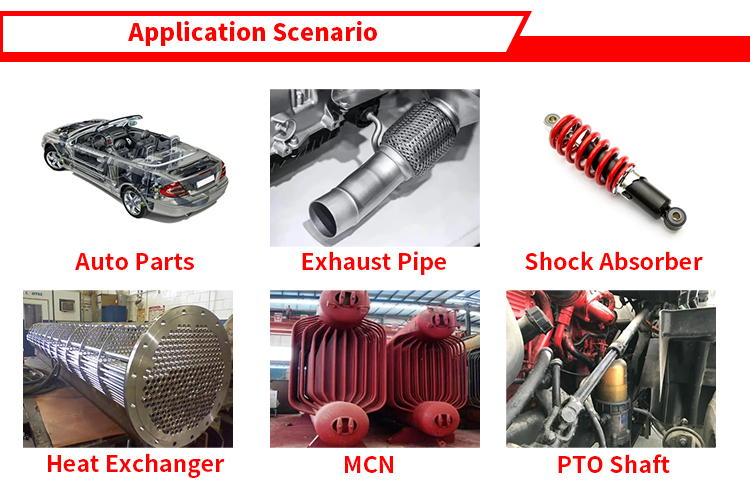

Application

Titanium straight pipes find applications in aerospace, chemical processing, medical implants, marine, and oil & gas industries due to their unique combination of properties.

Possible Alternative Grades

Grade 9 (Ti-3Al-2.5V)

Grade 12 (Ti-0.8Ni-0.3Mo)

Grade 23 (Ti-6Al-4V ELI)

We analyze and optimize the structure of our Hemispherical or Torispherical Dome Caps Welding in the design stage, which is very important to improve product quality and reduce production costs. The spirit of honesty is the foundation for our company and our employees to settle down and establish a good communication atmosphere and mutual trust. We will rely on the spirit of enterprise to make the company bigger and stronger, to forge brilliance again, and to always walk in the forefront of the times.

Hot Tags: welding titanium straight pipe, China, suppliers, manufacturers, factory, customized, wholesale, price, OEM, mill, producer, for sale, small diameter stainless steel tubing, en 8 pipe, piston and connecting rod, 1 5 dom tube, sa 214 carbon steel tubes, a335 p5