Since its establishment, sa335 p22, astm a335 p1, b111 c70600 has always been adhering to the tenet of "customer first, quality first", advocating the concept of "green, people-oriented, and innovative", and striving to provide every customer with environmentally friendly, healthy and comfortable sa335 p22, astm a335 p1, b111 c70600. We insist on giving equal importance to economic and social effects, give full play to and continuously enlarge our corporate advantages, and earnestly fulfill our social responsibilities in accelerating development. Owing to very good support, a variety of high quality merchandise, aggressive costs and efficient delivery, we love an excellent name among the our clients.

Welded Capillary Stainless Steel Tube: A Comprehensive Guide

Introduction

Welded capillary stainless steel tubes are highly specialized products used in various industries, including medical, pharmaceutical, and chemical processing. This article aims to provide a comprehensive guide to welded capillary stainless steel tubes, covering material, specification, key features, chemical composition, mechanical properties, physical properties, process performance, steel grade, application, and possible alternative grades.

Material and Specification

Welded capillary stainless steel tubes are typically manufactured using high-quality stainless steel grades such as 304, 316, or 321. These tubes are available in various sizes with outer diameters ranging from 0.5mm to 20mm and wall thicknesses ranging from 0.05mm to 2mm. The length of the tubes can be customized according to specific requirements.

Key Features

High corrosion resistance

Excellent heat resistance

Precise dimensions and tolerances

Smooth and uniform surface finish

Strong and durable construction

Suitable for high-pressure and high-temperature applications

Easy to clean and maintain

Welded construction for enhanced strength and integrity

Chemical Composition

The chemical composition of welded capillary stainless steel tubes varies depending on the grade of stainless steel used. Below is a table presenting the typical chemical composition of commonly used grades:

| Grade | C% | Si% | Mn% | P% | S% | Cr% | Ni% | Mo% |

| 304 | 0.08 | 0.75 | 2.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-10.5 | - |

| 316 | 0.08 | 0.75 | 2.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 |

| 321 | 0.08 | 0.75 | 2.00 | 0.045 | 0.030 | 17.0-19.0 | 9.0-12.0 | - |

Mechanical Properties

Welded capillary stainless steel tubes possess excellent mechanical properties, making them suitable for demanding applications. Below is a table presenting the typical mechanical properties of commonly used grades:

| Grade | Tensile Stremgth(MPa) | Yield Strength(MPa) | Elongation(%) |

| 304 | 515-730 | ≥205 | ≥40 |

| 316 | 515-690 | ≥205 | ≥40 |

| 321 | 515-730 | ≥205 | ≥40 |

Physical Properties

Welded capillary stainless steel tubes possess favorable physical properties that contribute to their exceptional performance. Below is a table presenting the typical physical properties of stainless steel tubes:

| Property | Value |

| Density (g/cm³) | 8.0-8.1 |

| Melting Point (°C) | 1398-1446 |

| Specific Heat (J/kg·K) | 500-600 |

| Thermal Conductivity (W/m·K) | 14-19 |

| Electrical Resistivity (µΩ·cm) | 72-78 |

Process Performance

Welded capillary stainless steel tubes are fabricated using advanced manufacturing processes. The welding methods employed ensure high-quality and defect-free products. These tubes exhibit excellent resistance to corrosion, heat, and pressure, making them suitable for critical applications in various industries.

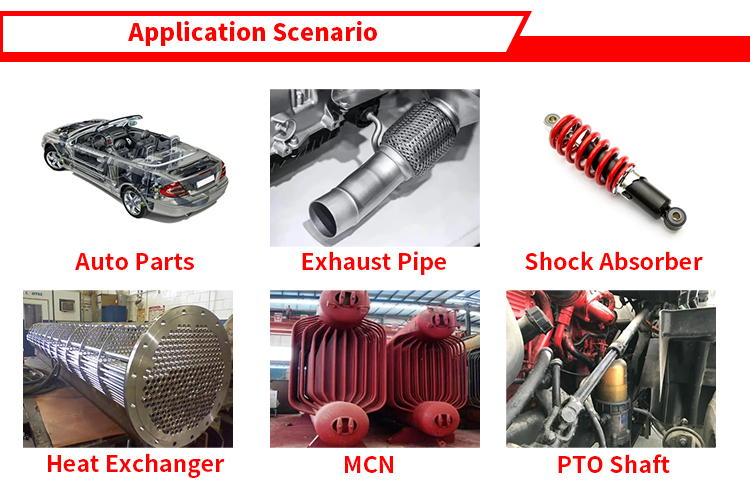

Steel Grade and Application

Different steel grades are selected based on specific application requirements. The most commonly used stainless steel grades for welded capillary tubes include 304, 316, and 321. These tubes find applications in numerous fields, including:

Medical devices and equipment

Pharmaceutical processing

Chemical processing

Precision instruments

Chromatography capillaries

Gas and liquid delivery systems

Possible Alternative Grades

While 304, 316, and 321 are widely used, depending on the specific application, alternative grades such as 310, 904L, or 2205 stainless steels may be considered. These alternative grades offer varying properties, including higher corrosion resistance or improved strength, to cater to specific requirements.

310 stainless steel: Enhanced high-temperature resistance

904L stainless steel: Superior corrosion resistance in aggressive environments

2205 stainless steel: Excellent strength and resistance to chloride stress corrosion cracking

We take high quality and high efficiency as the goal and customer satisfaction as the tenet, constantly optimizing and perfecting our High Quality 201 304 316 Factory Micro Bright Annealing Stainless Steel Capillary Tube / Tubing / Pipe. Our company not only has a strong production capacity to ensure sufficient inventory, but also customizes and develops ultrasonic products in different application fields according to customer needs. Our company always adheres to the tenet of 'survive by quality and development by technology', relying on the goal of 'win-win cooperation and common development', and wholeheartedly produces high-quality products for new and old users, which are sold well all over the world.

Hot Tags: welded capillary stainless steel tube, China, suppliers, manufacturers, factory, customized, wholesale, price, OEM, mill, producer, for sale, thin Wall steel Tube, steam tube boiler, ASTM A312 Seamless Stainless Steel Tube, 3 inch dom tubing, carbon steel piping, astm a815 uns s32750