It is our economic development purpose to keep our Capillary Stainless Steel Tube, Nickel Alloy Tube And Pipe, duplex steel pipes in sync with the times and our customers' consumption enjoyment in sync with the times. We firmly believe that the future will be a world of shared resources, unity and win-win results. We work closely with the main technical teams and have had good cooperation relationships with exceptional companies in the industry for a long time.

ASTM A53 SCH 10 Hot Finished Seamless Carbon Steel Pipe and Tubing

Material

ASTM A53 is a standard specification for pipe, steel, black and hot-dipped, zinc-coated, welded, and seamless, intended for mechanical and pressure applications. The SCH 10 designation refers to the wall thickness of the pipe, which is suitable for various applications in construction, manufacturing, and other industries.

Chemical Composition

The chemical composition of ASTM A53 SCH 10 pipes is crucial for ensuring the material's strength and durability. Below is a table summarizing the typical chemical composition:

| Element | Composition (%) |

| Carbon (C) | 0.25 max |

| Manganese (Mn) | 0.40 - 1.20 |

| Phosphorus (P) | 0.04 max |

| Sulfur (S) | 0.05 max |

| Silicon (Si) | 0.10 - 0.40 |

| Copper (Cu) | 0.20 max |

| Nickel (Ni) | 0.20 max |

| Chromium (Cr) | 0.15 max |

Mechanical Properties

The mechanical properties of ASTM A53 SCH 10 pipes are essential for their performance under various conditions. Below is a table summarizing these properties:

| Property | Value |

| Yield Strength (min) | 35,000 psi (240 MPa) |

| Tensile Strength (min) | 60,000 psi (415 MPa) |

| Elongation (min) | 20% |

| Hardness (Brinell) | 137 HB max |

Physical Properties

The physical properties of ASTM A53 SCH 10 pipes are important for understanding their behavior in different environments. Below is a table summarizing these properties:

| Property | Value |

| Density | 0.283 lb/in³ (7.85 g/cm³) |

| Melting Point | 2,500°F (1,370°C) |

| Thermal Conductivity | 43.5 BTU·in/(hr·ft²·°F) |

| Electrical Resistivity | 10.0 µΩ·m |

Process Performance

The process performance of ASTM A53 SCH 10 pipes is critical for their manufacturability and usability in various applications. Below is a table summarizing key performance metrics:

| Process | Performance Metric |

| Weldability | Good |

| Formability | Excellent |

| Machinability | Moderate |

| Corrosion Resistance | Moderate |

Application

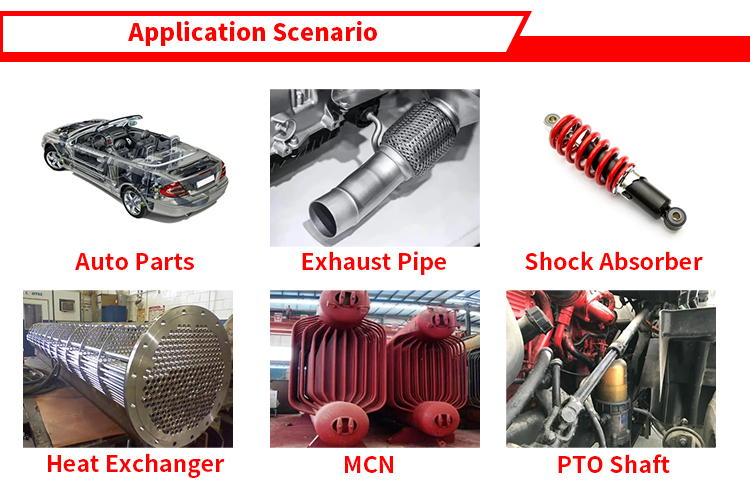

ASTM A53 SCH 10 pipes are widely used in various applications, including:

Construction: Structural applications, including beams and columns.

Manufacturing: Machinery and equipment fabrication.

Oil and Gas: Transporting fluids and gases in pipelines.

Water Supply: Used in municipal water systems.

Our company's tenet is to manufacture excellent Wp321, Wp347, Wps 31254 Sch 10~Sch 160 45/90/180 Long/Short Radius Stainless Steel Butt Welded Seamless Elbows, cultivate excellent talents, survive with high quality and give first priority to integrity. Our company pursues benefit by quality and develops by reputation. Customer satisfaction is the foundation and employee satisfaction is the guarantee. If you are not satisfied, please contact us in time.

Hot Tags: astm a53 sch 10 hot finished seamless carbon steel pipe and tubing, China, suppliers, manufacturers, factory, customized, wholesale, price, OEM, mill, producer, for sale, profile steel tube, hot finished seamless pipe, seamless mechanical tubing, 1026 dom tubing, astm a213 t5, a513 type 5