Extruded Fin Tube: A Comprehensive Guide

Material, Specification, Key Features

Extruded fin tubes are essential components in various industrial applications due to their unique design and efficiency. These tubes consist of a base tube with external fins that are extruded from the material, increasing the surface area for improved heat transfer. Here is an overview of the material, specifications, and key features of extruded fin tubes:

Material

Extruded fin tubes are commonly made from materials such as carbon steel, stainless steel, copper, or aluminum, depending on the application requirements.

Specification

The specifications for extruded fin tubes typically include dimensions such as outer diameter, wall thickness, fin height, fin density, and length, which are tailored to meet specific heat transfer needs.

Key Features

Enhanced Heat Transfer Efficiency: The extruded fins significantly increase the surface area, improving heat transfer efficiency.

Corrosion Resistance: Depending on the material used, extruded fin tubes can offer excellent resistance to corrosion, increasing durability.

High Strength: These tubes are known for their robust construction, providing stability in various operating conditions.

Chemical Composition

Below is a table presenting the typical chemical composition of extruded fin tubes made from carbon steel:

| Element | Composition (%) |

| Carbon (C) | 0.25 - 0.35 |

| Manganese (Mn) | 0.60 - 0.90 |

| Silicon (Si) | 0.15 - 0.35 |

| Phosphorus (P) | 0.04 (max) |

| Sulfur (S) | 0.05 (max) |

Mechanical Properties

The following table showcases the standard mechanical properties of extruded fin tubes:

| Property | Value |

| Tensile Strength | 400 - 600 MPa |

| Yield Strength | 250 - 400 MPa |

| Elongation | 20% (min) |

| Hardness (HRC) | 70 (max) |

Steel Grade

Common steel grades used for extruded fin tubes include ASTM A179, ASTM A214, and ASTM A106, among others, each offering specific benefits based on the application requirements.

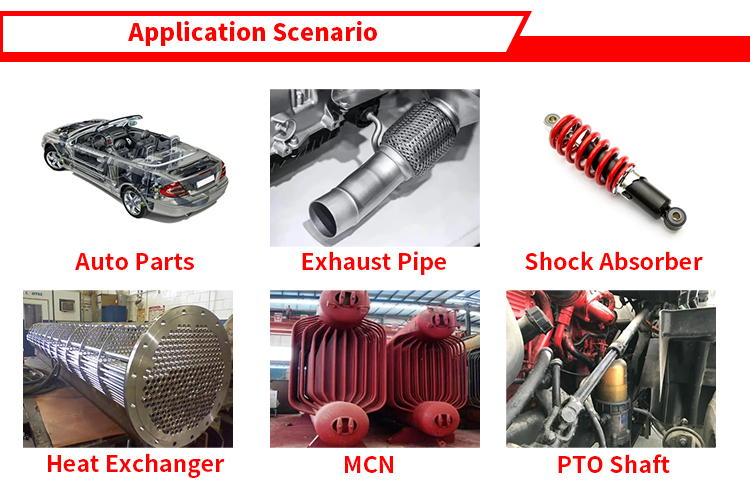

Application

Extruded fin tubes find applications in industries such as HVAC systems, heat exchangers, boilers, and refineries where efficient heat transfer is essential for operations.

Possible Alternative Grades

Depending on the requirement, alternative grades such as stainless steel 304, copper-nickel alloys, or aluminum can be considered for specific applications requiring unique properties such as higher corrosion resistance or thermal conductivity.

Hot Tags: extruded fin tube, China, suppliers, manufacturers, factory, customized, wholesale, price, OEM, mill, producer, for sale, brown fin tube